Building one locomotive motor from three

This locomotive motor is one of three in the shop right now. The steel mill they came from is desperate to get them back, so we're busy pulling parts from each to combine them into one, good-as-new motor that will go back to the mill.

When it comes to repairing legacy DC motors, particularly ones that work as hard as these ones, sometimes it's a game of mix 'n' match.

The guts of these three motors are all over the shop in various states of refurbishment.

These parts also belong to one of the locomotive motors. The black dust, crust and and chunks are from the coke ovens—just a little hint as to how challenging the environment is that these motors must work in.

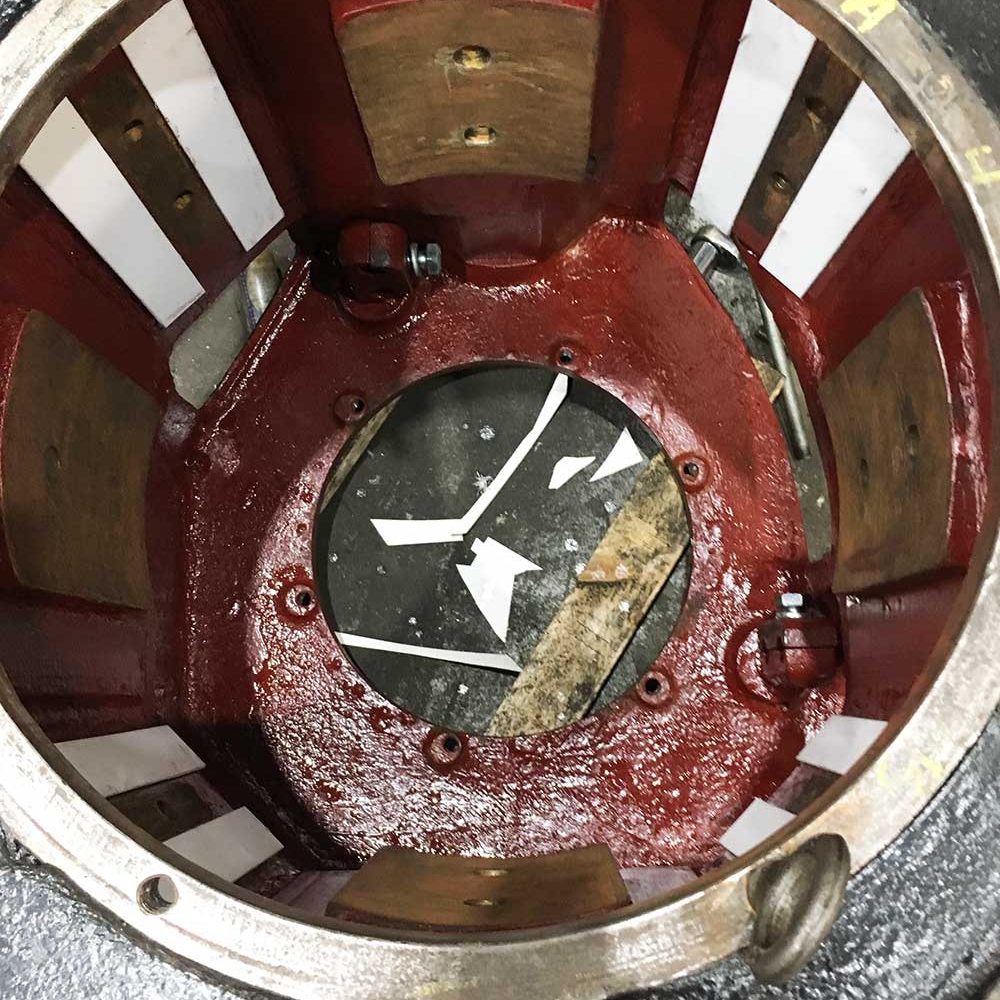

This is the shell of the motor that will eventually become the fully functional, completely rebuilt motor to be returned to the harsh environment of the steel mill.