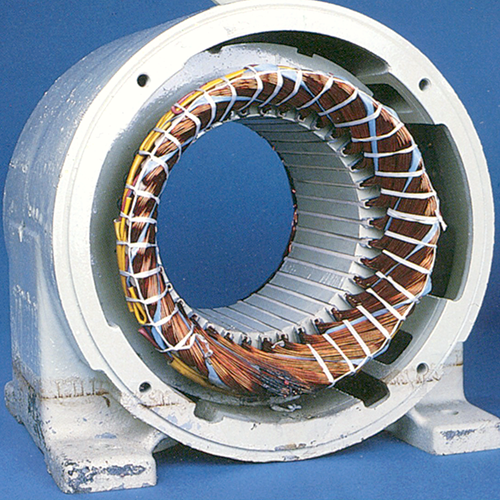

Troubleshooting a 3-phase stator winding failure [With examples] November 4, 2020

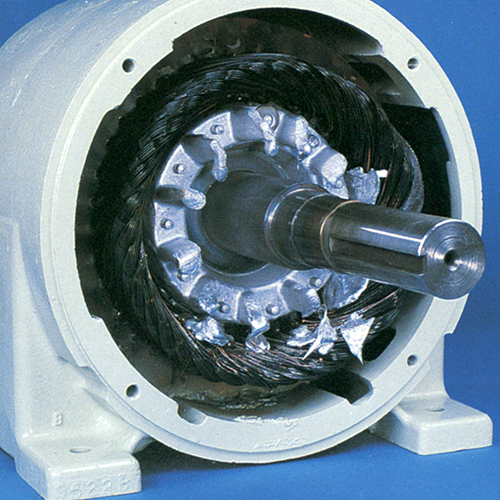

These photos show what typically happens to a three-phase stator winding on a bad day—one where it's subjected to poor electrical, mechanical or environmental conditions. Use the photos to help identify the cause of your stator failure so you can prevent those bad days in the future.

All imagery courtesy of EASA.

Single-phase winding failures

Wye-connected winding

Delta-connected winding

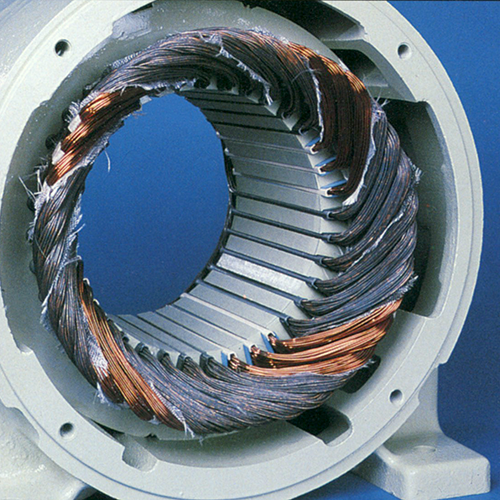

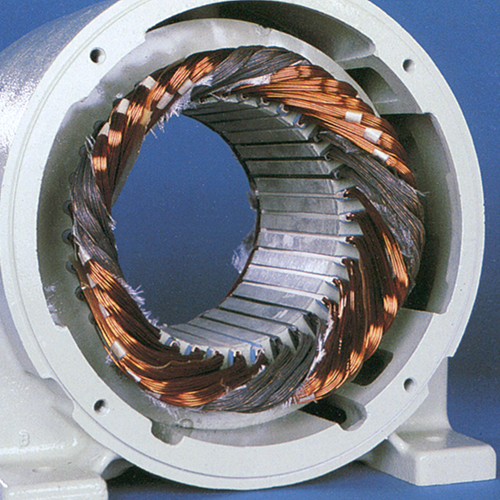

What you're looking at: All of these images show insulation damage in one phase of the stator winding.

What caused the problem: In the first two pics, the failures were the result of an open in one phase of the motor's power supply, which is often caused by an open contactor, blown fuse, bad connection or broken power line. In the third image, the insulation damage is likely due to unequal voltage between phases, which could be caused by a poor connection at the motor terminal, a weak spring (causing a high resistance contact), or unbalanced loads on the power source. (We cover these causes and more in our essential motor failure guide.)

Repair or replace? Our free online motor failure decision tool can help.

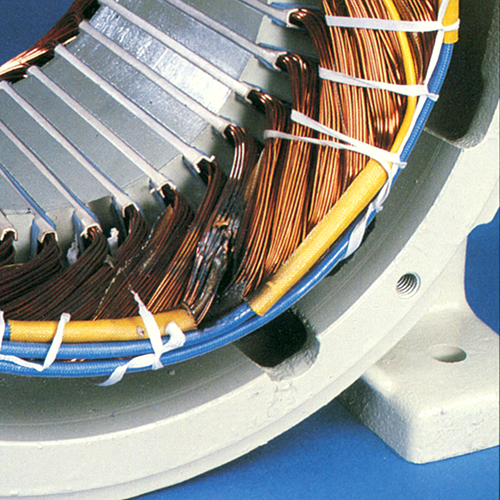

All-phase winding failures

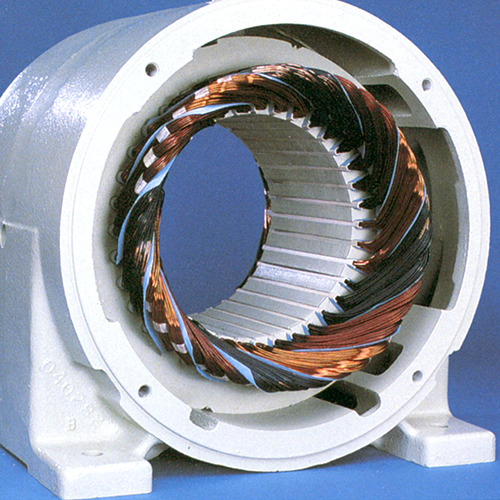

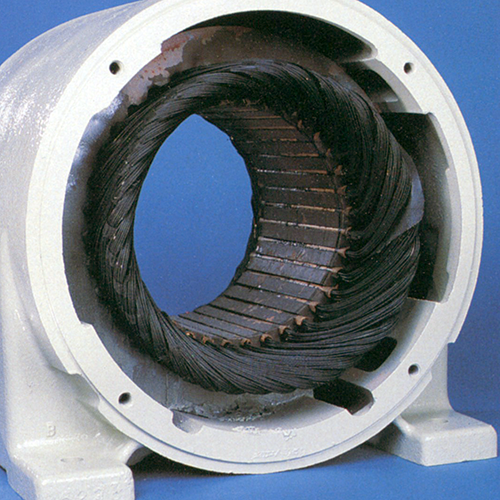

What you're looking at: Both of these images show toasted insulation in all phases of the stator winding. In the second pic the insulation damage is more significant.

What caused the problem: When insulation is destroyed in all phases as in the first image, it's usually caused by exceeding the load rating of the motor, but it could also be the result of under-voltage or voltage that exceeds NEMA standards. The severe thermal damage in the second pic is often caused by a locked rotor, which causes very high currents in the stator winding. Another reason for such significant insulation deterioration in all three phases is excessive starts or reversals.

Winding shorts

Winding shorted phase-to-phase

Winding shorted turn-to-turn

Winding with shorted coil

Winding with shorted connection

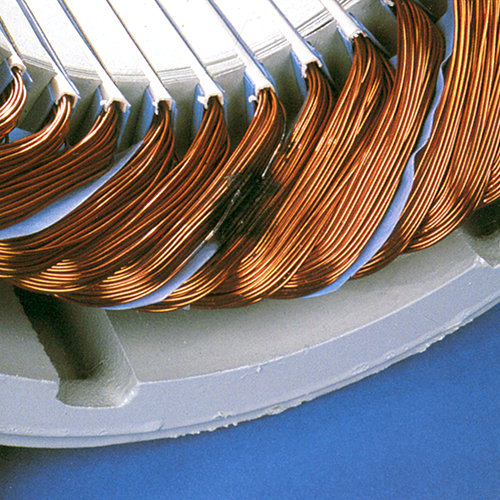

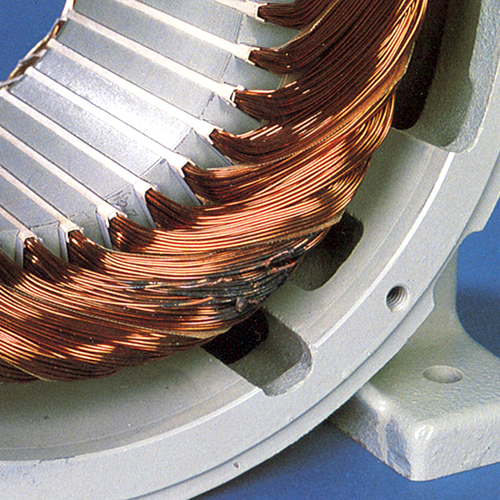

What you're looking at: The four pics in this section all show winding shorts. In all cases, the damage indicates insulation failure.

What caused the problem: This type of insulation failure is commonly caused by contaminants, abrasion, vibration or voltage surge.

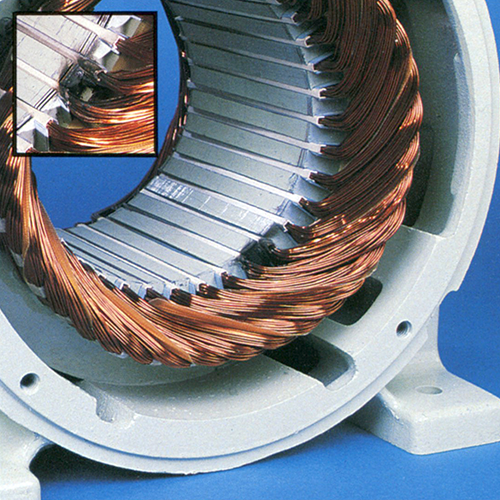

Grounded windings

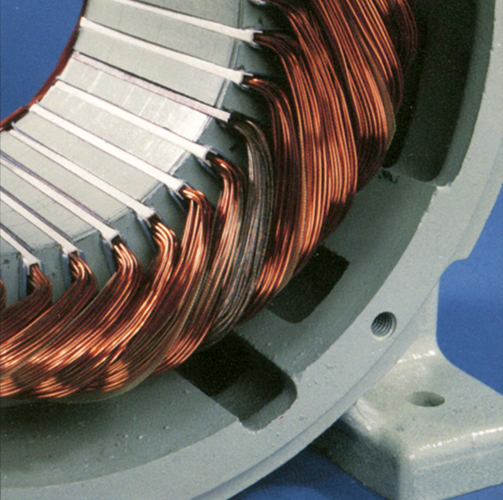

Winding grounded at edge of slot

Winding grounded in the slot

What you're looking at: The first image is of a winding grounded at the edge of the slot, while in the second the grounding occurred in the slot. Again, you're looking at insulation failure.

What caused the problem: The culprits are the same as for insulation failure due to shorts: contaminants, abrasion, vibration or voltage surge.

Winding failure due to voltage surge

What you're looking at: This pic shows the characteristic mark of voltage surge on winding insulation.

What caused the problem: To identify the cause of a voltage surge, consider capacitor discharges, lightning strikes, switching power circuits and solid-state power devices.